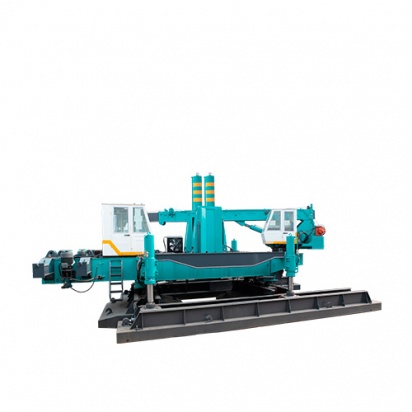

Hydraulic static pile driver

The pile-pressing mobile unit is a unique technology that is used in the installation of driven piles. The advantages of the system in preparing the foundation for construction makes it possible to immerse piles in dense buildings, in historical city centers, near dilapidated and emergency structures, in landslide zones and in other places where it is forbidden to immerse piles by the shock method and vibration immersion.

Piling mobile static

indentation machine

The pile-pressing installation is used for the installation of reinforced concrete piles (of various sections), pipes and sheet piles, driven (monolithic and hollow), rammed and shell supports.

The speed of pressing a 12 meter pile to a depth of 12 meters is (depending on the soil) no more than 7-10 minutes.

The pile is immersed in the ground under the influence of a gradually increasing static load. This technology of deepening does not violate the integrity of the support itself, and is one of the most effective methods of driving piles into the ground. Taking into account the time of the pile feeding and the movement of the machine, the estimated productivity of the IED is from 5 to 7 piles per hour with the correct choice of the machine according to the terms of reference.

Piling mobile static indentation machine

contains in its design

load frame, guide columns with pressing and clamping mechanisms placed on them, hydraulic cylinders for working and return travel, crane installation, as well as controls. The pile-pressing unit is anchored with metal weights (counterweights). In addition to the central columns, the unit has side columns, when moving the working equipment onto which the unit can press piles next to existing walls or other obstacles with a force of up to 70% of the nominal. Hydraulic cylinders are manufactured using REXROTH technology using Japanese MOK seals.

The scheme of the installation is simple - first, 2 hydraulic cylinders push the pile several meters at maximum speed, then all 4 cylinders work to increase the force. The pile pressing unit provides high accuracy of pile driving and continuous control of the pressing force, which is important for assessing the bearing capacity of the pile during the driving process.

The control of the indentation force allows you to optimize the design load and the number of piles in the project and, while ensuring the specified bearing capacity, to minimize the costs of building the foundation.

Pile-pressing installations are easy to operate, have a relatively low weight and overall dimensions, are transported disassembled on large-sized automobile platforms (trawls) for transporting construction equipment or on railway platforms.

The use of hydraulic pile-pressing installations is effective in spot construction, due to its higher productivity compared to the percussion method of driving piles, eliminating the destruction of pile heads, increasing the accuracy and reducing the energy consumption of their driving, the ability to measure the bearing capacity of each submerged pile, and improving working conditions.

Parameter Model | ZYC 80 | ZYC 100 | ZYC 120 | ZYC 150 | ZYC 180 | ZYC 220 | ZYC 260 | ZYC 300 | ZYC 360 | ZYC 460 | ZYC 600 | ZYC 680 | ZYC 860 | ZYC 960 | ZYC 1060 | ZYC 1260 | |

Rated piling pressure (10KN) | 80 | 100 | 120 | 150 | 180 | 220 | 260 | 300 | 360 | 460 | 600 | 680 | 860 | 960 | 1060 | 1260 | |

Piling speed (m/min) | Fast | 4.5 | 6.5 | 6.5 | 6.3 | 11 | 8.7 | 7.2 | 7.2 | 7.8 | 9.0 | 7.9 | 9.0 | 9.0 | 9.8 | 8.0 | 7.4 |

Low | 2.2 | 3.0 | 3.0 | 2.7 | 2.7 | 2.3 | 1.8 | 1.8 | 1.8 | 2.4 | 1.9 | 1.9 | 1.4 | 1.6 | 1.5 | 1.3 | |

Piling Stroke(m) | 1.6 | 1.6 | 1.6 | 1.6 | 1.9 | 1.9 | 1.9 | 1.9 | 1.9 | 1.9 | 1.9 | 1.9 | 1.9 | 1.9 | 1.9 | 1.9 | |

Pace(m) | Longitudinal | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.4 | 3.3 | 3.3 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 |

Horizontal | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | |

Steering angle(°) | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | 11 | |

Rise stroke(m) | 1.25 | 1.45 | 1.45 | 1.45 | 1.45 | 1.0 | 1.0 | 1.0 | 1.1 | 1.1 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | |

Max square pile(mm) | 300 | 350 | 350 | 400 | 400 | 500 | 500 | 550 | 550 | 550 | 550 | 550 | 550 | 650 | 650 | 650 | |

Max round pile(mm) | 300 | 400 | 400 | 400 | 400 | 500 | 500 | 600 | 600 | 600 | 600 | 600 | 600 | 800 | 800 | 1000 | |

Side piling space(m) | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.9 | 1.25 | 1.25 | 1.4 | 1.4 | 1.6 | 1.6 | 1.7 | 1.8 | |

Corner piling space(m) | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1.0 | 1.0 | 1.8 | 2.5 | 2.5 | 2.8 | 2.8 | 3.2 | 3.2 | 3.4 | 3.6 | |

Lifting crane(t) | 5 | 8 | 8 | 8 | 8 | 8 | 12 | 12 | 16 | 20 | 20 | 25 | 25 | 25 | 35 | 35 | |

Max. Hoisting pile length(m) | 9 | 12 | 12 | 12 | 12 | 12 | 14 | 14 | 15 | 16 | 16 | 17 | 17 | 17 | 18 | 18 | |

Power (KW) | Piling engin | 18.5 | 37 | 37 | 37 | 60 | 60 | 60 | 60 | 74 | 111 | 111 | 111 | 148 | 148 | 164 | 180 |

Crane engin | 11 | 22 | 22 | 22 | 22 | 22 | 30 | 30 | 30 | 30 | 30 | 37 | 37 | 37 | 37 | 37 | |

Main dimension (m) | Working lenth | 5.4 | 6.7 | 9.1 | 9.45 | 9.45 | 9.9 | 11 | 12 | 12.7 | 13.0 | 14.1 | 14.7 | 15.0 | 16.0 | 16.9 | 17.0 |

Working width | 3.9 | 4.2 | 4.7 | 4.7 | 4.8 | 5.6 | 6.0 | 6.2 | 7.2 | 7.5 | 8.12 | 8.3 | 8.6 | 8.8 | 9.3 | 9.9 | |

Transportation height | 2.0 | 2.7 | 2.9 | 2.9 | 2.9 | 3.0 | 3.0 | 3.1 | 3.15 | 3.25 | 3.3 | 3.3 | 3.35 | 3.35 | 3.4 | 3.4 | |

Total weight (t) | 80 | 100 | 120 | 150 | 180 | 220 | 260 | 300 | 360 | 460 | 600 | 680 | 860 | 960 | 1060 | 1260 | |